Filled Grade PTFE Rod

PTFE is available in many different Grades as Virgin TEFLON, Glass Filed PTFE, Carbon Filled PTFE, Bronze Filled PTFE, Graphite Filled PTFE, Stainless Steel Filled PTFE, Chemically Modified PTFE, Carbon / Coke Filled PTFE, Bronze + Molybdenum Disulphide Filled PTFE, Aluminium Oxide Filled PTFE, Calcium Fluoride Filled PTFE, , Mica Filled PTFE, Glass + MoS2 Filled PTFE, MoS2 Filled PTFE, Chemically Modified PTFE etc.

We can also provide custom made in these PTFE Rods in different shapes and sizes which is made from Filled Grade PTFE by Compression Process.

Filled Grade PTFE Rod products are generally used for High compressive strength, Self-lubrication, for any number of chemical, electrical and mechanical components (such as seals, caps, etc.) where the outstanding performance characteristics of PTFE are required.

Filled Grade PTFE Rods are available in diameters ranging from 10 mm to 300 mm with Maximum Length of 300 mm.

- Dimension Detail

- Technical Specfication

- Available Grades

- Application

Diameter: 10 To 400 MM (Std.)

Length : 300 MM (Std.)

Specific Length and Diameter / Circle available as per customer’s requirement.

material :

- Virgin PTFE

- 15% Peek PTFE

- 15 To 25% Glass Filled PTFE

- 25 To 35% Carbon Filled PTFE

- 15% Graphite Filled PTFE

- 40 to 60% Bronzed Filled PTFE

- 5 to 15% Aluminum Oxide Filled PTFE

- 5 to 10% Stainless Steel Filled PTFE

- 5 to 10% Mica Filled PTFE

- 55% + 5% Bronzed + Molybdenum Disulphide Filled PTFE

- 15% + 5% Glass + MOS2 Filled PTFE

Colour : Based on Filled Grade Material.

RESIN MAKE : GFL 610 Mixed with Fiber and Metal

PTFE Resin standard : D1457 / D4894

ASTM standard : ASTM D3295

Temperature Range : 200°C to +260°C

Density : 2.1 – 2.2 g/cm³

The Filled grades of PTFE can be compounded & customized for specific service conditions & applications. Filled PTFE grades have specific properties improvement based on filler, type of filler & percentage of filler.

There are many popular filled grades PTFE Products brand named as Trexonn, Turcite B, Rulon AR, Rulon AJ Gold having specific properties, designed for specific service and applications.

VESCOAT INDIA, manufactures similar grades of PTFE Products branded as Trexonn, Turcite B, Rulon AR, Rulon AJ Gold.

Nonstandard Series can be made available on request subject to minimum quantity

- Food Processing Industries

- Chemical Industries

- Pharmaceutical Industries

- Pump & Valve Manufacturers

- Marine Industrial Sector

- Automobile Industries

- Hydraulic Equipment Industry

- Process Industry Equipment Manufacturers

- Electrical AND ELECTRONIC Appliances Manufacturers

- Dimension Detail

- Technical Specfication

- Available Grades

- Application

Diameter: 10 To 400 MM (Std.)

Length : 300 MM (Std.)

Specific Length and Diameter / Circle available as per customer’s requirement.

material :

- Virgin PTFE

- 15% Peek PTFE

- 15 To 25% Glass Filled PTFE

- 25 To 35% Carbon Filled PTFE

- 15% Graphite Filled PTFE

- 40 to 60% Bronzed Filled PTFE

- 5 to 15% Aluminum Oxide Filled PTFE

- 5 to 10% Stainless Steel Filled PTFE

- 5 to 10% Mica Filled PTFE

- 55% + 5% Bronzed + Molybdenum Disulphide Filled PTFE

- 15% + 5% Glass + MOS2 Filled PTFE

Colour : Based on Filled Grade Material.

RESIN MAKE : GFL 610 Mixed with Fiber and Metal

PTFE Resin standard : D1457 / D4894

ASTM standard : ASTM D3295

Temperature Range : 200°C to +260°C

Density : 2.1 – 2.2 g/cm³

The Filled grades of PTFE can be compounded & customized for specific service conditions & applications. Filled PTFE grades have specific properties improvement based on filler, type of filler & percentage of filler.

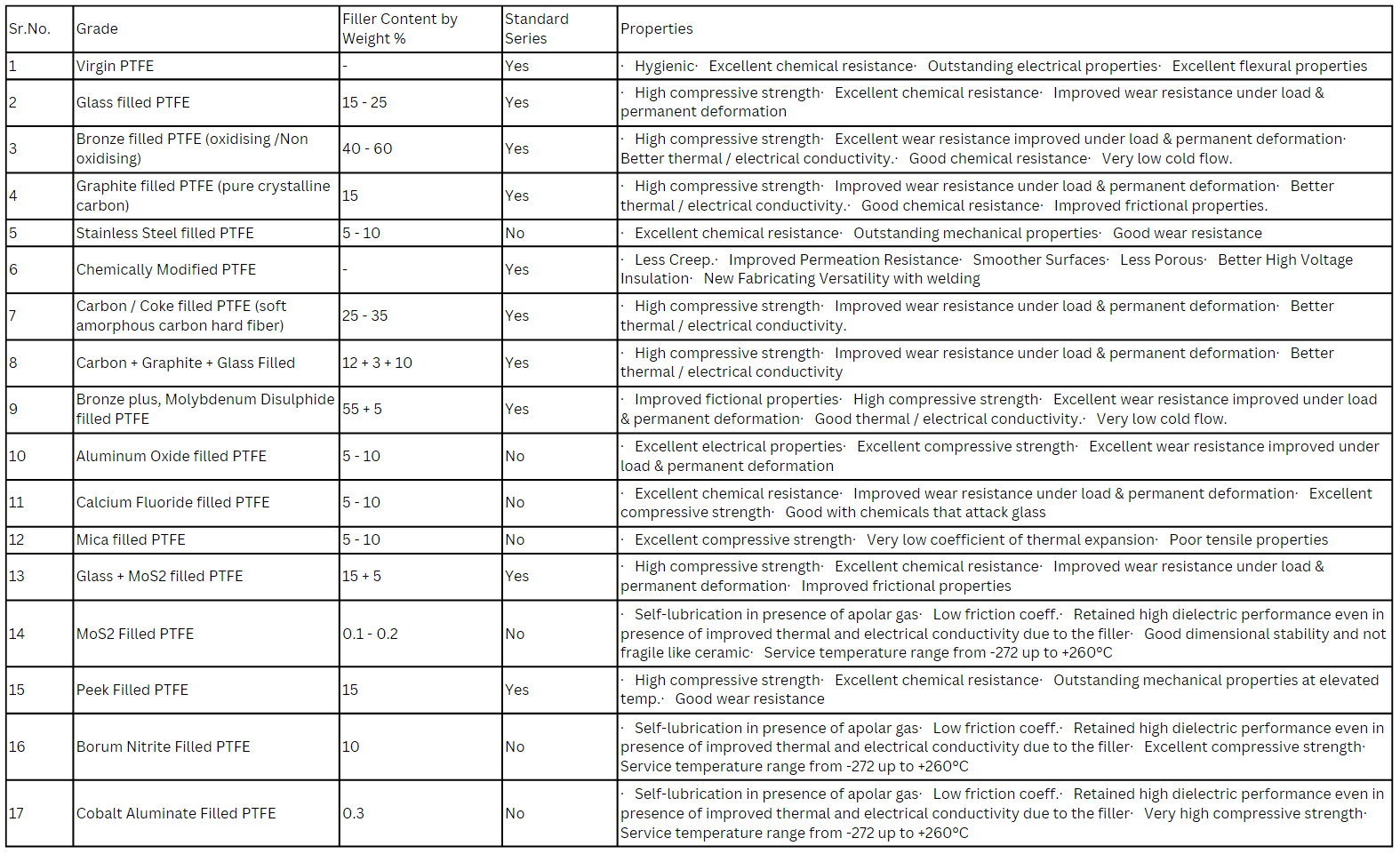

Sr.No. | Grade | Filler Content by Weight % | Standard Series | Properties |

1 | Virgin PTFE | - | Yes | · Hygienic · Excellent chemical resistance · Outstanding electrical properties · Excellent flexural properties |

2 | Glass filled PTFE | 15 - 25 | Yes | · High compressive strength · Excellent chemical resistance · Improved wear resistance under load & permanent deformation |

3 | Bronze filled PTFE (oxidising /Non oxidising) | 40 - 60 | Yes | · High compressive strength · Excellent wear resistance improved under load & permanent deformation · Better thermal / electrical conductivity. · Good chemical resistance · Very low cold flow. |

4 | Graphite filled PTFE (pure crystalline carbon) | 15 | Yes | · High compressive strength · Improved wear resistance under load & permanent deformation · Better thermal / electrical conductivity. · Good chemical resistance · Improved frictional properties. |

5 | Stainless Steel filled PTFE | 5 - 10 | No | · Excellent chemical resistance · Outstanding mechanical properties · Good wear resistance |

6 | Chemically Modified PTFE | - | Yes | · Less Creep. · Improved Permeation Resistance · Smoother Surfaces · Less Porous · Better High Voltage Insulation · New Fabricating Versatility with welding |

7 | Carbon / Coke filled PTFE (soft amorphous carbon hard fiber) | 25 - 35 | Yes | · High compressive strength · Improved wear resistance under load & permanent deformation · Better thermal / electrical conductivity. |

8 | Carbon + Graphite + Glass Filled | 12 + 3 + 10 | Yes | · High compressive strength · Improved wear resistance under load & permanent deformation · Better thermal / electrical conductivity |

9 | Bronze plus, Molybdenum Disulphide filled PTFE | 55 + 5 | Yes | · Improved fictional properties · High compressive strength · Excellent wear resistance improved under load & permanent deformation · Good thermal / electrical conductivity. · Very low cold flow. |

10 | Aluminum Oxide filled PTFE | 5 - 10 | No | · Excellent electrical properties · Excellent compressive strength · Excellent wear resistance improved under load & permanent deformation |

11 | Calcium Fluoride filled PTFE | 5 - 10 | No | · Excellent chemical resistance · Improved wear resistance under load & permanent deformation · Excellent compressive strength · Good with chemicals that attack glass |

12 | Mica filled PTFE | 5 - 10 | No | · Excellent compressive strength · Very low coefficient of thermal expansion · Poor tensile properties |

13 | Glass + MoS2 filled PTFE | 15 + 5 | Yes | · High compressive strength · Excellent chemical resistance · Improved wear resistance under load & permanent deformation · Improved frictional properties |

14 | MoS2 Filled PTFE | 0.1 - 0.2 | No | · Self-lubrication in presence of apolar gas · Low friction coeff. · Retained high dielectric performance even in presence of improved thermal and electrical conductivity due to the filler · Good dimensional stability and not fragile like ceramic · Service temperature range from -272 up to +260°C |

15 | Peek Filled PTFE | 15 | Yes | · High compressive strength · Excellent chemical resistance · Outstanding mechanical properties at elevated temp. · Good wear resistance |

16 | Borum Nitrite Filled PTFE | 10 | No | · Self-lubrication in presence of apolar gas · Low friction coeff. · Retained high dielectric performance even in presence of improved thermal and electrical conductivity due to the filler · Excellent compressive strength · Service temperature range from -272 up to +260°C |

17 | Cobalt Aluminate Filled PTFE | 0.3 | No | · Self-lubrication in presence of apolar gas · Low friction coeff. · Retained high dielectric performance even in presence of improved thermal and electrical conductivity due to the filler · Very high compressive strength · Service temperature range from -272 up to +260°C |

There are many popular filled grades PTFE Products brand named as Trexonn, Turcite B, Rulon AR, Rulon AJ Gold having specific properties, designed for specific service and applications.

VESCOAT INDIA, manufactures similar grades of PTFE Products branded as Trexonn, Turcite B, Rulon AR, Rulon AJ Gold.

Nonstandard Series can be made available on request subject to minimum quantity

- Food Processing Industries

- Chemical Industries

- Pharmaceutical Industries

- Pump & Valve Manufacturers

- Marine Industrial Sector

- Automobile Industries

- Hydraulic Equipment Industry

- Process Industry Equipment Manufacturers

- Electrical AND ELECTRONIC Appliances Manufacturers