Ptfe Lined Butterfly Valve

- Home

- Lined Products

- Ptfe Lined Butterfly Valve

Ptfe Lined Butterfly Valve

We have wide range in Lined Butterfly Valve. We are manufacturing best quality products as per domestic and international standards. We have our own manufacturing unit and have well experience & expertise team.

PTFE Lined butterfly valves Used for corrosive fluids and high-purity applications.

Lined Butterfly Valves are available in Wafer Style which is suitable to fit between two flanges as per ANSI 150#, DIN, & JIS Standards.

- Dimension Detail

- Technical Specification

- Features

- Application

Material Standard

- Areas where highly corrosive materials are used in the chemical process and plants.

- Industries where the critical application like food, pharma and fine chemicals.

- To control environment pollution.

- Best quality in class with excellent performance.

- Excellent corrosion resistance to the chemicals.

- Maintenance Free / Long Services life cycle / Easy Installable, ensuring cost reduction in production and maintenance.

- High Voltage electric spark test – all lined components.

- Standard Hydraulic Test(15 kg/cm²) of body and seat(10 kg/cm²)

- Virgin lining materials used – FEP/PFA.

- Size : 50 NB to 500 NB

- Thickness : 3.0 to 3.5 mm Mini. Over all wetted parts.

- Spark Test : 15k.v.D.C

- Type : FEP/PFA

- Services : (FEP) Max – 160°C

- : (PFA) Max – 205°C

- Dimension Detail

- Features

- TECHNICAL SPECIFICATIONS & DESIGN STANDARD

- Application

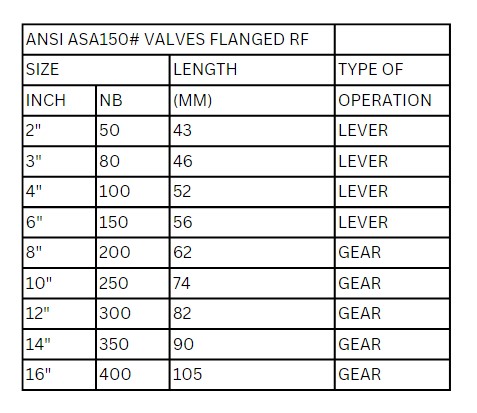

ANSI ASA150# VALVES FLANGED RF |

| ||

SIZE | LENGTH | TYPE OF | |

INCH | NB | (MM) | OPERATION |

2" | 50 | 43 | LEVER |

3" | 80 | 46 | LEVER |

4" | 100 | 52 | LEVER |

6" | 150 | 56 | LEVER |

8" | 200 | 62 | GEAR |

10" | 250 | 74 | GEAR |

12" | 300 | 82 | GEAR |

14" | 350 | 90 | GEAR |

16" | 400 | 105 | GEAR |

- Areas where highly corrosive materials are used in the chemical process and plants.

- Industries where the critical application like food, pharma and fine chemicals.

- To control environment pollution.

- Best quality in class with excellent performance.

- Excellent corrosion resistance to the chemicals.

- Maintenance Free / Long Services life cycle / Easy Installable, ensuring cost reduction in production and maintenance.

- High Voltage electric spark test – all lined components.

- Standard Hydraulic Test(15 kg/cm²) of body and seat(10 kg/cm²)

- Virgin lining materials used – FEP/PFA.

- Size : 50 NB to 500 NB

- Thickness : 3.0 to 3.5 mm Mini. Over all wetted parts.

- Spark Test : 15k.v.D.C

- Type : FEP/PFA

- Services : (FEP) Max – 160°C

- : (PFA) Max – 205°C

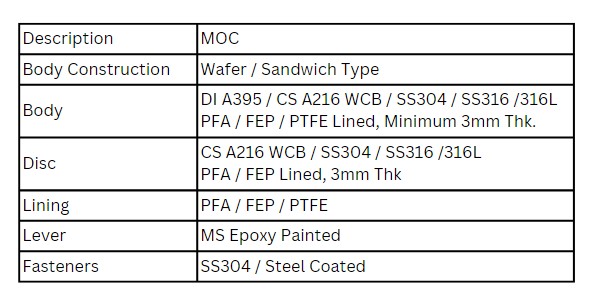

Description | MOC |

Body Construction | Wafer / Sandwich Type |

Body | DI A395 / CS A216 WCB / SS304 / SS316 /316L PFA / FEP / PTFE Lined, Minimum 3mm Thk. |

Disc | CS A216 WCB / SS304 / SS316 /316L PFA / FEP Lined, 3mm Thk |

Lining | PFA / FEP / PTFE |

Lever | MS Epoxy Painted |

Fasteners | SS304 / Steel Coated |

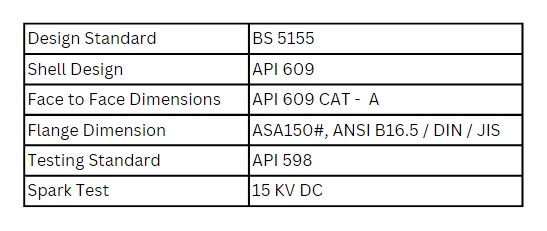

Design Standard | BS 5155 |

Shell Design | API 609 |

Face to Face Dimensions | API 609 CAT - A |

Flange Dimension | ASA150#, ANSI B16.5 / DIN / JIS |

Testing Standard | API 598 |

Spark Test | 15 KV DC |

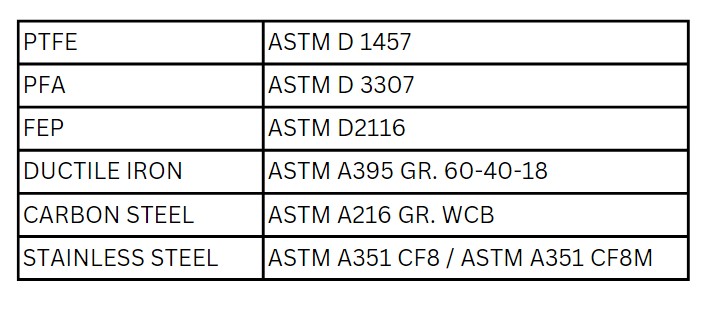

Material Standard

PTFE | ASTM D 1457 |

PFA | ASTM D 3307 |

FEP | ASTM D2116 |

DUCTILE IRON | ASTM A395 GR. 60-40-18 |

CARBON STEEL | ASTM A216 GR. WCB |

STAINLESS STEEL | ASTM A351 CF8 / ASTM A351 CF8M |

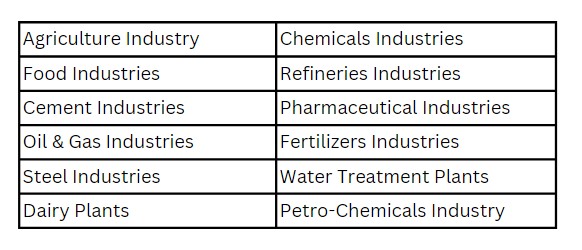

Agriculture Industry | Chemicals Industries |

Food Industries | Refineries Industries |

Cement Industries | Pharmaceutical Industries |

Oil & Gas Industries | Fertilizers Industries |

Steel Industries | Water Treatment Plants |

Dairy Plants | Petro-Chemicals Industry |