Ptfe Lined Swing Check Valve

- Home

- Lined Products

- Ptfe Lined Swing Check Valve

Ptfe Lined Swing Check Valve

We have wide range in Lined Swing Check Valve. We are manufacturing best quality products as per domestic and international standards. We have our own manufacturing unit and have well experience & expertise team.

A swing check valve is a butterfly-style check valve in which the disc, the movable part to block the flow, swings on a hinge or grunion, either onto the seat to block reverse flow or off the seat to allow forward flow. The seat opening cross-section may be perpendicular to the center line between the two ports or at an angle. Swing check valve shut off depends on gravity and reverse flow. The pivot point of the swing check valve is outside the edge of the disc and, the greater the head, the greater the possibility that the fluid will flow back through the valve before the disc can shut off.

- Dimension Detail

- Technical Specification

- Features

- Application

Material Standard

The PFA lined Swing Check Valve are developed for use in extremely corrosive applications, full port design can be installed either vertically and dependent upon application horizontally as well.

Lining material such as PFA and conductive PFA have exceptional corrosion resistance.

The Lined Swing Check valves are available for the connection with DIN EN 1092-1 or ANSI B16.5 flanges from DN 15-½” to DN 200-8”.

A swing check valve is a butterfly-style check valve in which the disc, the movable part to block the flow, swings on a hinge or grunion, either onto the seat to block reverse flow or off the seat to allow forward flow. The seat opening cross-section may be perpendicular to the center line between the two ports or at an angle. Although swing check valves can come in various sizes, large check valves are often swing check valves. Swing check valve shut off depends on gravity and reverse flow. The pivot point of the swing check valve is outside the edge of the disc and, the greater the head, the greater the possibility that the fluid will flow back through the valve before the disc can shut off. To affect complete shut off, the disc of a swing check valve must travel through a 90 angle arc to the swing check valve seat.

- Dimension Detail

- Features

- Application

- TECHNICAL SPECIFICATIONS & DESIGN STANDARD

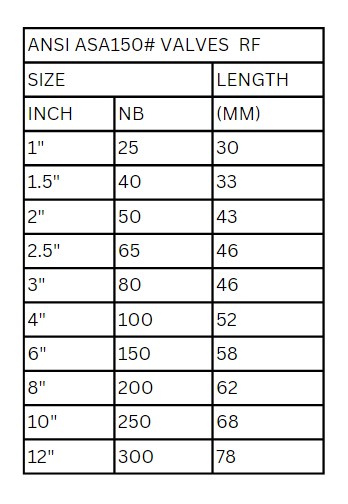

ANSI ASA150# VALVES RF | ||

SIZE | LENGTH | |

INCH | NB | (MM) |

1" | 25 | 30 |

1.5" | 40 | 33 |

2" | 50 | 43 |

2.5" | 65 | 46 |

3" | 80 | 46 |

4" | 100 | 52 |

6" | 150 | 58 |

8" | 200 | 62 |

10" | 250 | 68 |

12" | 300 | 78 |

Material Standard

PTFE | ASTM D 1457 |

PFA | ASTM D 3307 |

FEP | ASTM D2116 |

DUCTILE IRON | ASTM A395 GR. 60-40-18 |

CARBON STEEL | ASTM A216 GR. WCB |

STAINLESS STEEL | ASTM A351 CF8 / ASTM A351 CF8M |

The PFA lined Swing Check Valve are developed for use in extremely corrosive applications, full port design can be installed either vertically and dependent upon application horizontally as well.

Lining material such as PFA and conductive PFA have exceptional corrosion resistance.

The Lined Swing Check valves are available for the connection with DIN EN 1092-1 or ANSI B16.5 flanges from DN 15-½” to DN 200-8”.

A swing check valve is a butterfly-style check valve in which the disc, the movable part to block the flow, swings on a hinge or grunion, either onto the seat to block reverse flow or off the seat to allow forward flow. The seat opening cross-section may be perpendicular to the center line between the two ports or at an angle. Although swing check valves can come in various sizes, large check valves are often swing check valves. Swing check valve shut off depends on gravity and reverse flow. The pivot point of the swing check valve is outside the edge of the disc and, the greater the head, the greater the possibility that the fluid will flow back through the valve before the disc can shut off. To affect complete shut off, the disc of a swing check valve must travel through a 90 angle arc to the swing check valve seat.

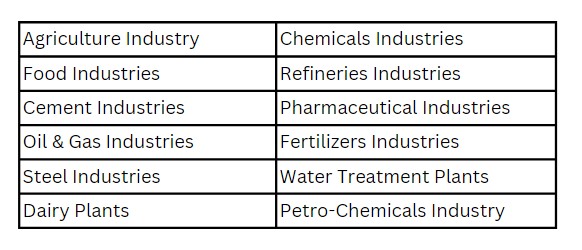

Agriculture Industry | Chemicals Industries |

Food Industries | Refineries Industries |

Cement Industries | Pharmaceutical Industries |

Oil & Gas Industries | Fertilizers Industries |

Steel Industries | Water Treatment Plants |

Dairy Plants | Petro-Chemicals Industry |

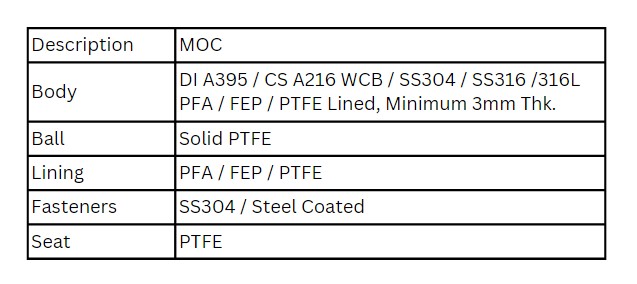

Description | MOC |

Body | DI A395 / CS A216 WCB / SS304 / SS316 /316L PFA / FEP / PTFE Lined, Minimum 3mm Thk. |

Ball | Solid PTFE |

Lining | PFA / FEP / PTFE |

Fasteners | SS304 / Steel Coated |

Seat | PTFE |

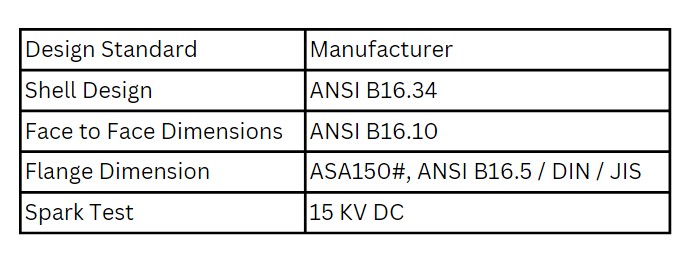

Design Standard | Manufacturer |

Shell Design | ANSI B16.34 |

Face to Face Dimensions | ANSI B16.10 |

Flange Dimension | ASA150#, ANSI B16.5 / DIN / JIS |

Spark Test | 15 KV DC |

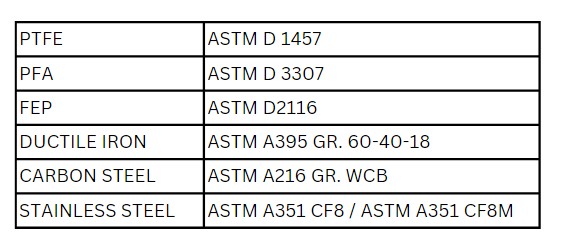

Material Standard

PTFE | ASTM D 1457 |

PFA | ASTM D 3307 |

FEP | ASTM D2116 |

DUCTILE IRON | ASTM A395 GR. 60-40-18 |

CARBON STEEL | ASTM A216 GR. WCB |

STAINLESS STEEL | ASTM A351 CF8 / ASTM A351 CF8M |