PTFE Lined Manhole Cover

- Home

- Lined Products

- PTFE Lined Manhole Cover

PTFE Lined Manhole Cover

VESCOAT INDIA specialize in manufacturing and export quality manhole cover in PFA LINED MANHOLE COVER AND FEP LINED MANHOLE COVER. We use high quality raw materials that are sourced from authentic vendors of the market. Our Lined Manhole cover assembly is known for sturdy construction, perfect finish and longer service life and it is duly checked on various parameters to ensure zero-defect. Our manhole cover suitable for various glass lined reactors (GMM, Swiss Glascoat and Didetrich etc.)

- Manhole Cover Consist Of

- Technical Specification

- Notes

- Application

- All pipes have SOFF flange both side with one end loose flange and fixed flange at the other end. For A105 Flange: lap joint flange at one end and fixed flange at the other end.

- Lined pipes are available up to a Length of 6 meters max.

- All fittings are supplied with fixed cast or welded flanges only.

- Suitable vent holes are provided for all pipes & fittings.

- All pipe work will be supplied with suitable wooden end covers to protect the flare faces.

- Material test certificates will be provided for all raw materials

- Weld buttons will be provided for pipe spools more than 300 mm long.

- The plastic liner flare will replace the raised face portion of the flange.

- Manhole Cover Consist Of

- Technical Specification

- Notes

- Application

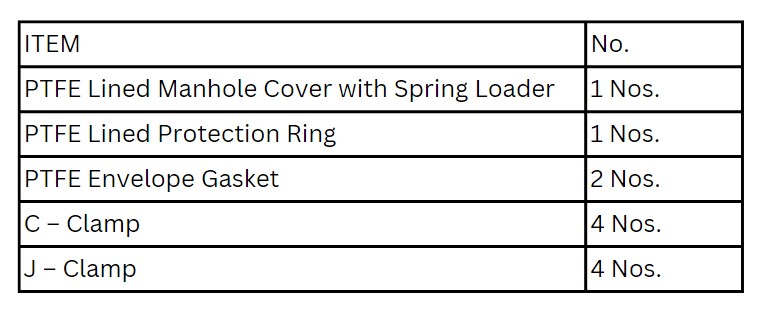

| ITEM | No. |

| PTFE Lined Manhole Cover with Spring Loader | 1 Nos. |

| PTFE Lined Protection Ring | 1 Nos. |

| PTFE Envelope Gasket | 2 Nos. |

| C – Clamp | 4 Nos. |

| J – Clamp | 4 Nos. |

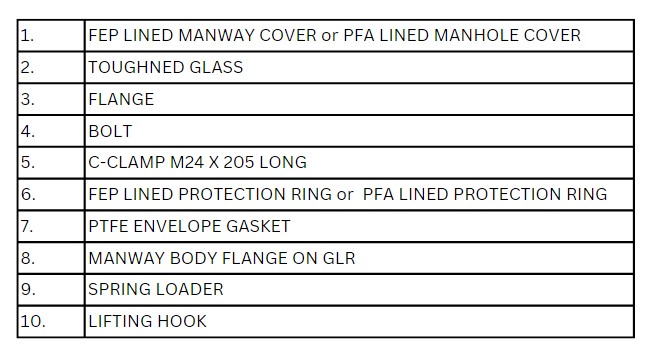

| 1. | FEP LINED MANWAY COVER or PFA LINED MANHOLE COVER |

| 2. | TOUGHNED GLASS |

| 3. | FLANGE |

| 4. | BOLT |

| 5. | C-CLAMP M24 X 205 LONG |

| 6. | FEP LINED PROTECTION RING or PFA LINED PROTECTION RING |

| 7. | PTFE ENVELOPE GASKET |

| 8. | MANWAY BODY FLANGE ON GLR |

| 9. | SPRING LOADER |

| 10. | LIFTING HOOK |

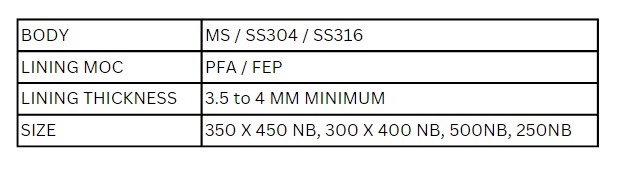

| BODY | MS / SS304 / SS316 |

| LINING MOC | PFA / FEP |

| LINING THICKNESS | 3.5 to 4 MM MINIMUM |

| SIZE | 350 X 450 NB, 300 X 400 NB, 500NB, 250NB |

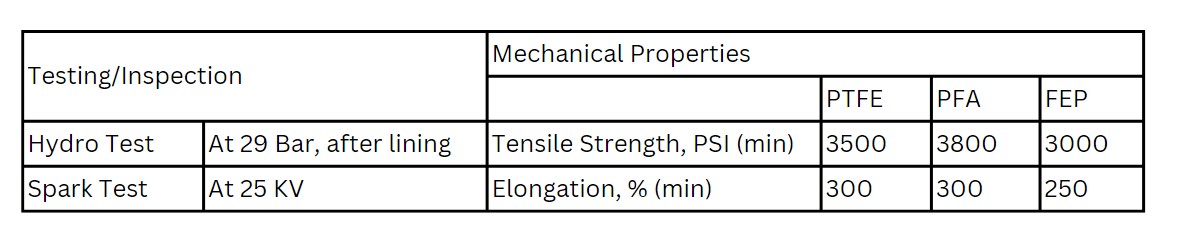

| Testing/Inspection | Mechanical Properties | ||||

| PTFE | PFA | FEP | |||

| Hydro Test | At 29 Bar, after lining | Tensile Strength, PSI (min) | 3500 | 3800 | 3000 |

| Spark Test | At 25 KV | Elongation, % (min) | 300 | 300 | 250 |

- All pipes have SOFF flange both side with one end loose flange and fixed flange at the other end. For A105 Flange: lap joint flange at one end and fixed flange at the other end.

- Lined pipes are available up to a Length of 6 meters max.

- All fittings are supplied with fixed cast or welded flanges only.

- Suitable vent holes are provided for all pipes & fittings.

- All pipe work will be supplied with suitable wooden end covers to protect the flare faces.

- Material test certificates will be provided for all raw materials

- Weld buttons will be provided for pipe spools more than 300 mm long.

- The plastic liner flare will replace the raised face portion of the flange.

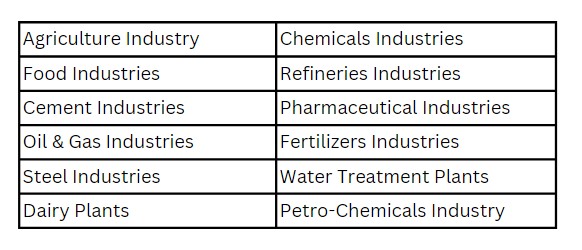

Agriculture Industry | Chemicals Industries |

Food Industries | Refineries Industries |

Cement Industries | Pharmaceutical Industries |

Oil & Gas Industries | Fertilizers Industries |

Steel Industries | Water Treatment Plants |

Dairy Plants | Petro-Chemicals Industry |