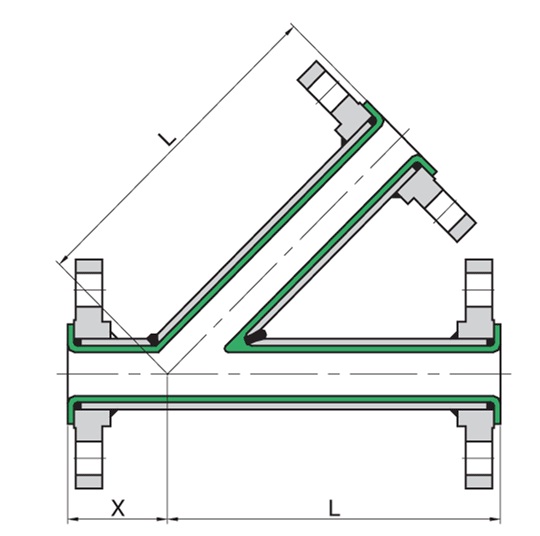

Lined Lateral tee

- Home

- Lined Products

- Lined Lateral tee

Lined Lateral tee

VescoaT supplies and manufacturer of PTFE Lined Lateral Tee, We also manufacture in PFA / FEP / HDPE lined Lateral Tee by using most advance and hitech techniques. Non Standard size available on request.

- Dimension Detail

- Technical Specification

- Notes

- Application

- All Lined Lateral Tee have Fix Flange on Both Side ( SOFF flange both side with one end loose flange and fixed flange at the other side or Both Side Loose Flange as on Request) For A105 Flange: lap joint flange at one end and fixed flange at the other end.

- Suitable vent holes are provided for all fittings.

- All Fittings work will be supplied with suitable wooden end covers to protect the flare faces.

- Material test certificates will be provided for all raw materials

- The plastic liner flare will replace the raised face portion of the flange.

- Dimension Detail

- Technical Specification

- Notes

- Application

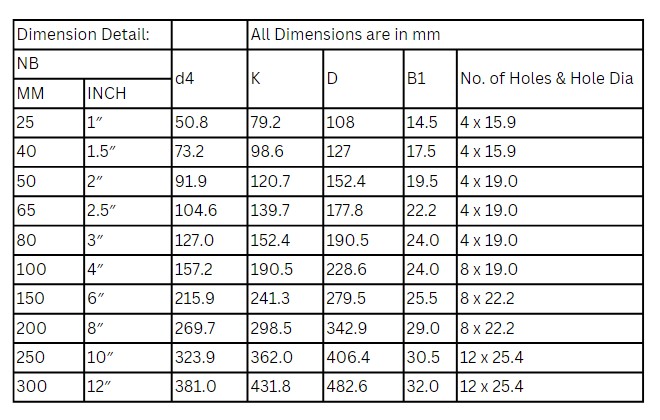

| Dimension Detail: | All Dimensions are in mm | |||||

| NB | d4 | K | D | B1 | No. of Holes & Hole Dia | |

| MM | INCH | |||||

| 25 | 1″ | 50.8 | 79.2 | 108 | 14.5 | 4 x 15.9 |

| 40 | 1.5″ | 73.2 | 98.6 | 127 | 17.5 | 4 x 15.9 |

| 50 | 2″ | 91.9 | 120.7 | 152.4 | 19.5 | 4 x 19.0 |

| 65 | 2.5″ | 104.6 | 139.7 | 177.8 | 22.2 | 4 x 19.0 |

| 80 | 3″ | 127.0 | 152.4 | 190.5 | 24.0 | 4 x 19.0 |

| 100 | 4″ | 157.2 | 190.5 | 228.6 | 24.0 | 8 x 19.0 |

| 150 | 6″ | 215.9 | 241.3 | 279.5 | 25.5 | 8 x 22.2 |

| 200 | 8″ | 269.7 | 298.5 | 342.9 | 29.0 | 8 x 22.2 |

| 250 | 10″ | 323.9 | 362.0 | 406.4 | 30.5 | 12 x 25.4 |

| 300 | 12″ | 381.0 | 431.8 | 482.6 | 32.0 | 12 x 25.4 |

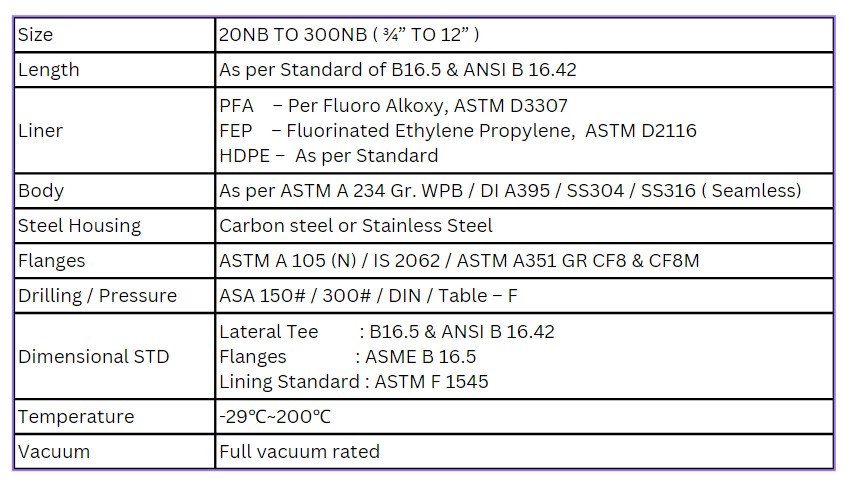

| Size | 20NB TO 300NB ( ¾” TO 12” ) |

| Length | As per Standard of B16.5 & ANSI B 16.42 |

| Liner | PFA – Per Fluoro Alkoxy, ASTM D3307 FEP – Fluorinated Ethylene Propylene, ASTM D2116 HDPE – As per Standard |

| Body | As per ASTM A 234 Gr. WPB / DI A395 / SS304 / SS316 ( Seamless) |

| Steel Housing | Carbon steel or Stainless Steel |

| Flanges | ASTM A 105 (N) / IS 2062 / ASTM A351 GR CF8 & CF8M |

| Drilling / Pressure | ASA 150# / 300# / DIN / Table – F |

| Dimensional STD | Lateral Tee : B16.5 & ANSI B 16.42 Flanges : ASME B 16.5 Lining Standard : ASTM F 1545 |

| Temperature | -29℃~200℃ |

| Vacuum | Full vacuum rated |

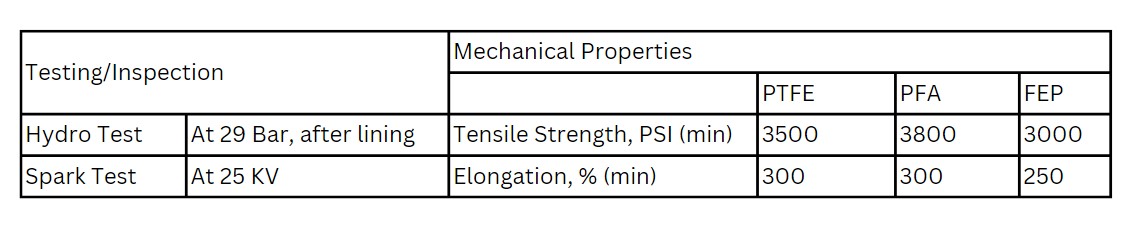

| Testing/Inspection | Mechanical Properties | ||||

| PTFE | PFA | FEP | |||

| Hydro Test | At 29 Bar, after lining | Tensile Strength, PSI (min) | 3500 | 3800 | 3000 |

| Spark Test | At 25 KV | Elongation, % (min) | 300 | 300 | 250 |

- All Lined Lateral Tee have Fix Flange on Both Side ( SOFF flange both side with one end loose flange and fixed flange at the other side or Both Side Loose Flange as on Request) For A105 Flange: lap joint flange at one end and fixed flange at the other end.

- Suitable vent holes are provided for all fittings.

- All Fittings work will be supplied with suitable wooden end covers to protect the flare faces.

- Material test certificates will be provided for all raw materials

- The plastic liner flare will replace the raised face portion of the flange.

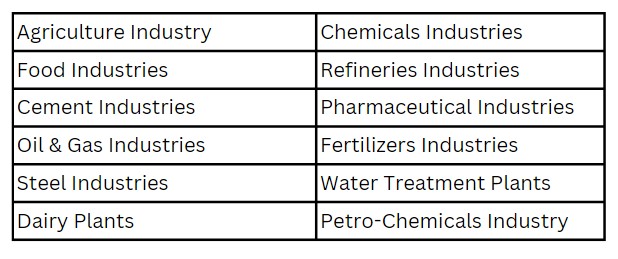

Agriculture Industry | Chemicals Industries |

Food Industries | Refineries Industries |

Cement Industries | Pharmaceutical Industries |

Oil & Gas Industries | Fertilizers Industries |

Steel Industries | Water Treatment Plants |

Dairy Plants | Petro-Chemicals Industry |