Ptfe Lined Ball Valve

- Home

- Lined Valevs

- Ptfe Lined Ball Valve

Ptfe Lined Ball Valve

We have wide range in ptfe lined ball valves with or without Actuator. We are manufacturing best quality products as per domestic and international standards. We have our own manufacturing unit and have well experience & expertise team.

We are manufacturing wide range of the 2pc design ball valves.Manually lever operated, gear operated, actuator operated. Our Valves Supplied with Anti-Static Devices for Protection Against Potentially Dangerous Electrostatic Discharge

- Dimension Detail

- Technical Specifications

- Features

- Application

- Interior valve bodies as well as the stem and ball are individually lined with PFA or PVDF/FEP

- Ball is fully encapsulated in PFA/FEP.

- Anti-blow out stem assembly for preventing stem blow out even when top gear is disassembled

- Short pattern face to face dimension in accordance with ANSI B16.10 and ANSI B 16.5, 150 lbs.(flange dimension) – facilitating replacement of fully lined or sleeved plug valves with ptfe lined ball valves without altering existing pipework

- Valves supplied with anti-static devices for protection against potentially dangerous electrostatic discharge

- Free floating Ball Valve Principle ensures the ball seals against the downstream seat ring giving a positive sealing force even when line pressure is low

- All inherent design features of a conventional ball valve such as low torque, quarter-turn operation, bubble tight shut off and a minimum pressure drop.

- Dimension Detail

- FEATUES

- Application

- TECHNICAL SPECIFICATIONS & DESIGN STANDARD

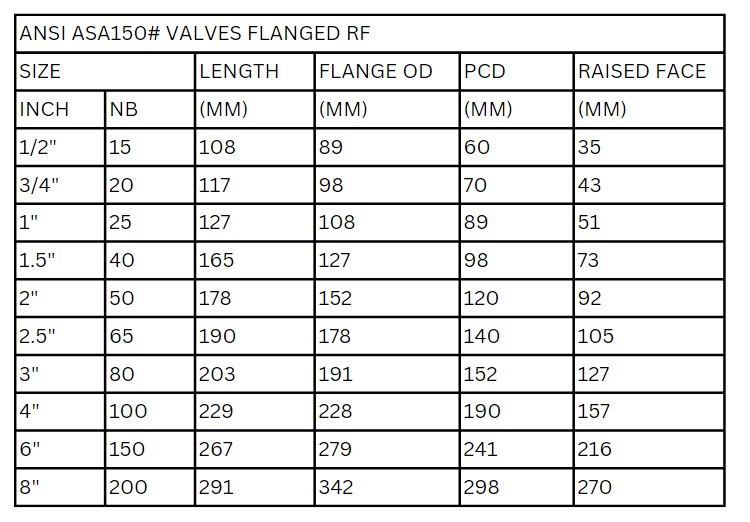

| ANSI ASA150# VALVES FLANGED RF | |||||

| SIZE | LENGTH | FLANGE OD | PCD | RAISED FACE | |

| INCH | NB | (MM) | (MM) | (MM) | (MM) |

| 1/2" | 15 | 108 | 89 | 60 | 35 |

| 3/4" | 20 | 117 | 98 | 70 | 43 |

| 1" | 25 | 127 | 108 | 89 | 51 |

| 1.5" | 40 | 165 | 127 | 98 | 73 |

| 2" | 50 | 178 | 152 | 120 | 92 |

| 2.5" | 65 | 190 | 178 | 140 | 105 |

| 3" | 80 | 203 | 191 | 152 | 127 |

| 4" | 100 | 229 | 228 | 190 | 157 |

| 6" | 150 | 267 | 279 | 241 | 216 |

| 8" | 200 | 291 | 342 | 298 | 270 |

- Interior valve bodies as well as the stem and ball are individually lined with PFA or PVDF/FEP

- Ball is fully encapsulated in PFA/FEP.

- Anti-blow out stem assembly for preventing stem blow out even when top gear is disassembled

- Short pattern face to face dimension in accordance with ANSI B16.10 and ANSI B 16.5, 150 lbs.(flange dimension) – facilitating replacement of fully lined or sleeved plug valves with ptfe lined ball valves without altering existing pipework

- Valves supplied with anti-static devices for protection against potentially dangerous electrostatic discharge

- Free floating Ball Valve Principle ensures the ball seals against the downstream seat ring giving a positive sealing force even when line pressure is low

- All inherent design features of a conventional ball valve such as low torque, quarter-turn operation, bubble tight shut off and a minimum pressure drop.

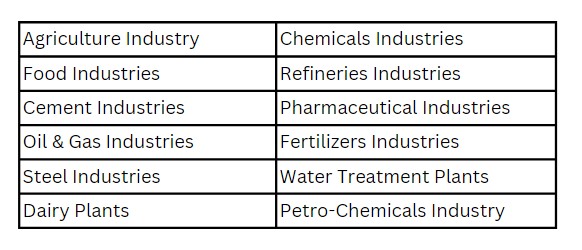

Agriculture Industry | Chemicals Industries |

Food Industries | Refineries Industries |

Cement Industries | Pharmaceutical Industries |

Oil & Gas Industries | Fertilizers Industries |

Steel Industries | Water Treatment Plants |

Dairy Plants | Petro-Chemicals Industry |

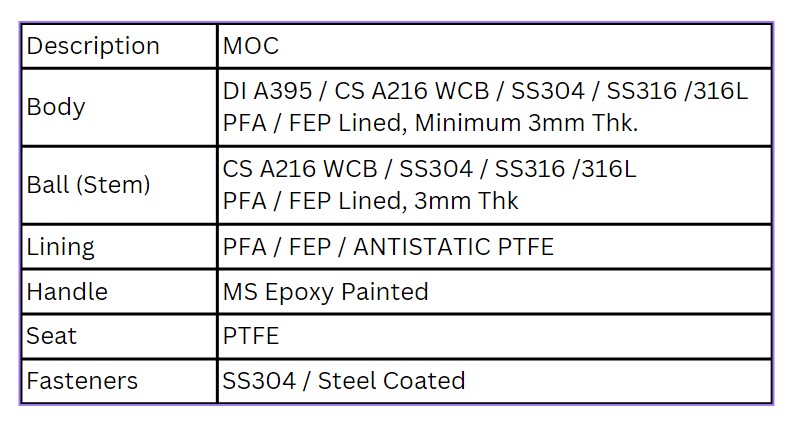

Description | MOC |

Body | DI A395 / CS A216 WCB / SS304 / SS316 /316L PFA / FEP Lined, Minimum 3mm Thk. |

Ball (Stem) | CS A216 WCB / SS304 / SS316 /316L PFA / FEP Lined, 3mm Thk |

Lining | PFA / FEP / ANTISTATIC PTFE |

Handle | MS Epoxy Painted |

Seat | PTFE |

Fasteners | SS304 / Steel Coated |

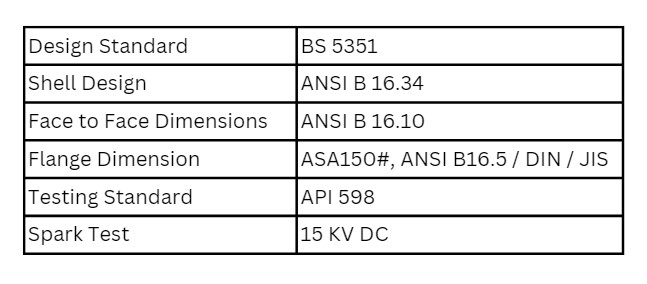

Design Standard | BS 5351 |

Shell Design | ANSI B 16.34 |

Face to Face Dimensions | ANSI B 16.10 |

Flange Dimension | ASA150#, ANSI B16.5 / DIN / JIS |

Testing Standard | API 598 |

Spark Test | 15 KV DC |